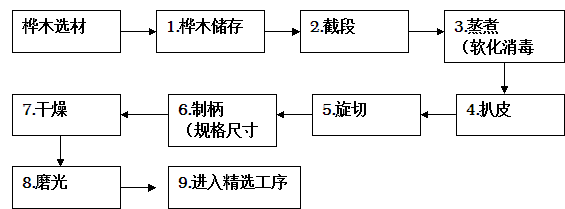

The production of ice cream handles can be processed according to various specifications and models provided by customers. In the process of processing, the usual procedures are as follows:

1. Birch storage ensures uniformity of color in later use.

2. Cut sections according to the specifications of the ice cream handle to avoid wood waste.

3. Put into the wood digester for soaking and cooking, which can also increase the toughness of the board. In the process of soaking and cooking, no processing AIDS and additives should be added.

Ice cream bar production process (Figure 1)

4. Rotary cutting: Rotary cutting according to the thickness of the ice cream handle required by the customer.

5. Handle making: Shape the cut plate.

6. Drying: Dry the handle of the ice cream handle embryo, drying is usually transmitted by circulating bellows one-time drying.

7. Polishing: After drying, enter polishing. The purpose of polishing is to remove burrs and increase the gloss of the ice cream handle itself.

8. Enter the next link to select the finished product, packaging and warehousing.